Zipper woven sleeve for automotive equipment

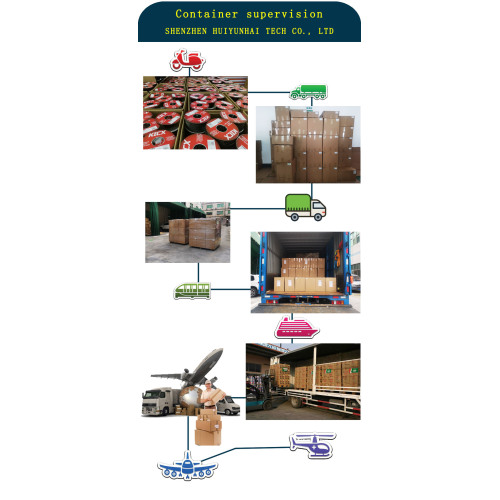

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 500 Meter |

| Transportation: | Ocean,Air |

| Port: | Shenzhen Port,Yantian Port |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 500 Meter |

| Transportation: | Ocean,Air |

| Port: | Shenzhen Port,Yantian Port |

Model No.: HYH

Brand: HYH

Sample: Free

Color: Black

Delivery Time: 5 Days

Certification: Other

Usage: Electric Wire

Material: PET,PP

Type: Other

Zipper Head Color: Custom

| Selling Units | : | Meter |

| Package Type | : | roll pack and carton packing |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

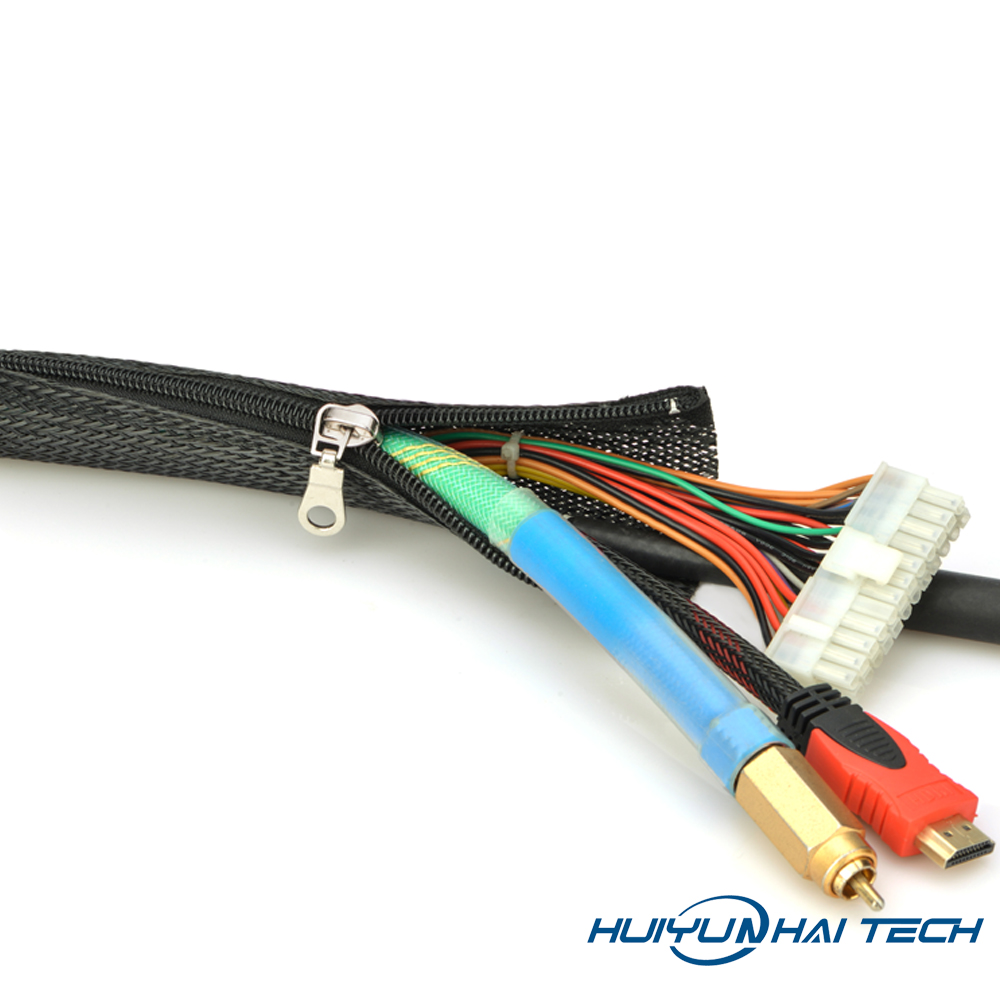

The Zipper Braided Sleeve is made of polyester single-layer mesh with zipper stitching. It has good heat dissipation, stretchability, fire resistance, wear resistance, easy and convenient operation, etc. The zipper structure is good for internal wire harness protection or reassembly. Applications: wire harnesses, automotive equipment, railroad tracks, and general industrial manufacturing where double protection is required.

Description of zipper braided sleeve

Whether your problem is getting past large connectors or not wanting to disconnect complex cable runs, this zipper cable sleeve side-entry braided wrap is an ideal cable management solution. Zip up cable sleeving is great for wire installations in which only a small portion of the bundle needs to be concealed, and is easily removed and relocated at your convenience.

Our expandable braided zipper sleeving offers exceptional cable protection, but is really used to tidy up exposed cable runs. TV, computer and phone setups can all have a clean and organized cables instead of those ugly cable nests.

Automotive and marine applications such as aftermarket speaker systems, GPS or other component accessories that may need cable organization can benefit from this Braided sleeving.

A great feature to this side entry zipper cable wrap is the ability to expand, this is due to the loose braided weave which allows the flexibility if your cords create a tight fit.

The purpose of putting a protective cover on the wire harness is to reflect the quality and stability of a wire harness protection braided sleeve, and it is inseparable from the outer protective layer, such as the wire harness protection braided sleeve used outside the wire harness, which is good or bad. Some aspects determine the quality of a set of harnesses. During these years, when visiting customers, I often see or hear the customer's reaction. Some mechanical protection of the wire harness used to protect the wire harness protects the quality of the braided sleeve. For example, some machines will generate heat when working, which requires the material of the wire harness protection braided sleeve to have better temperature resistance, but often see It is a lot of wire harnesses that have been used for a year or even months to protect the braided sleeve from breaking, aging, falling off, and more serious melting or fire.

Available in a multitude of sizes and lengths to accommodate most cable setups, zipper sleeving does not need the ends seared by a hot knife, nor the use of cable ties to keep from fraying or cables falling out.

a. High abrasion resistance

b. Flame retardant

c. Thermal insulation performance

d. Flexibility

e. Environmental protection

f. Protect the wiring harness

Features of zipper sleeve

Zipper expandable braided zipper sleeving offers exceptional cable protection, but is really used to tidy up exposed cable runs. TV, computer and phone setups can all have a clean and organized cables instead of those ugly cable nests.

Automotive and marine applications such as aftermarket speaker systems, GPS or other component accessories that may need cable organization can benefit from this braided sleeving.

A great feature to this side entry zipper cable wrap is the ability to expand, this is due to the loose braided weave which allows the flexibility if your cords create a tight fit.

Available in a multitude of sizes and lengths to accommodate most cable setups, zipper sleeving does not need the ends seared by a hot knife, nor the use of cable ties to keep from fraying or cables falling out.

Applications of zipper braided sleeve

Cable ,wire equipments and all kinds of pipes .Meanwhile ,providing a strong protection in the automotive ,machinery and equipment ,railway ,light rail and other areas .

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.