Tin Copper Sleeve For Wire Cable Grounding

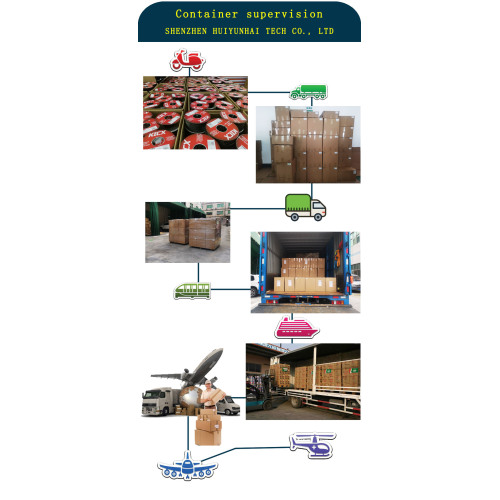

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 500 Meter |

| Port: | Shenzhen Port,Yantian Port |

| Payment Type: | T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 500 Meter |

| Port: | Shenzhen Port,Yantian Port |

Model No.: HYH

Brand: HYH

Color: Other

Certification: Other

Usage: Electric Wire

Material: Other

Type: Other

Lead Time: 5 Days

Sample: Custom

| Selling Units | : | Meter |

| Package Type | : | roll pack and carton packing |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Features of copper sleeves:

Features of copper sleeves:

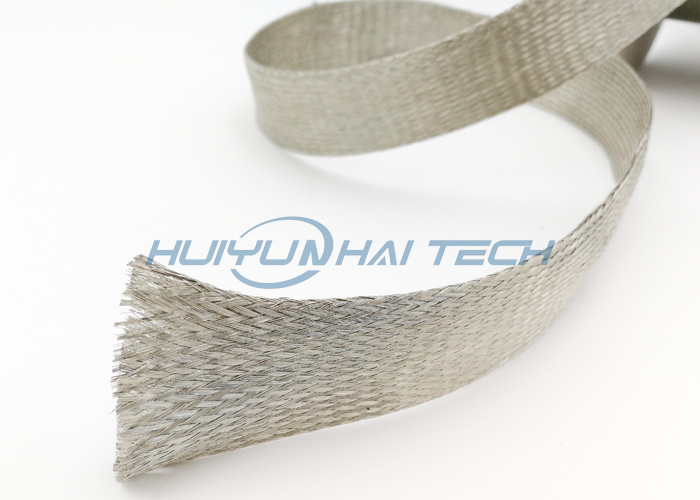

With two of the most popular Braided sleeving materials combined, our Tinned Copper Braided Sleeving offers abrasion resistance, decent EMI/RFI shielding and a unique design pattern that adds a high-tech look to automotive and PCB board applications.

Due to the weave design that blends the two materials, this braided sleeving has a decent expansion ratio and exceptional flexibility which means the tin coated copper and the sleeving is easy to work with.

The braided copper tape is made by braiding a number of spindles(24,36,48) of best quality round.

wires(0.10, 0.15, 0.20) or soft Sn-coated wires(0.10, 0.15) to become single layer or multi layers type.

DC resistivity of the copper braided tape (20°C) is less than 0.022Ω.mm2/m.

1). Nominal Voltage: 600V.

2). Temperature Range: -60°C to +1500°C

3). O.D.Allowance: ±0.10mm.

4) Copper filament material

5) Good EMI shielding

6) Cut and abrasion resistant

7) Flexible&easy to install

8) Copper foil shielding sleeving is woven with copper foil filament,it is used for various electrical.

and industrial fields where EMI shielding, excellent protection and lightweight are required.

9) It is lighter and more flexible than tinned copper braided sleeving,it is a perfect conbination.

of economy and durability,it can be used as connectors with highly flexible and easily to install.

Usages for Tinned Copper Braided Sleeving

Tinned copper braided wire is used as flexible jointing wire of electric appliance, switch appliance electric stove and storage battery etc. such as Cable, CRT Assembly Wire, Television, Computer Monitor.ETC signal pickup instruments. Braided copper wire can be provided rolled flat or in tubular form. Flat braids are generally used for flexible connections, electrical leads and grounding straps.

1. copper braided sleeves are used for the flexible conductor of electric installation,switch gear,electric frunace,storage battery,etc.

2. Tinned copper braided wire is used as flexible jointing wire of electric appliance, switch appliance electric stove and storage battery etc. such as Cable, CRT Assembly Wire, Television, Computer Monitor.ETC signal pickup instruments. Braided copper wire can be provided rolled flat or in tubular form. Flat braids are generally used for flexible connections, electrical leads and grounding straps.

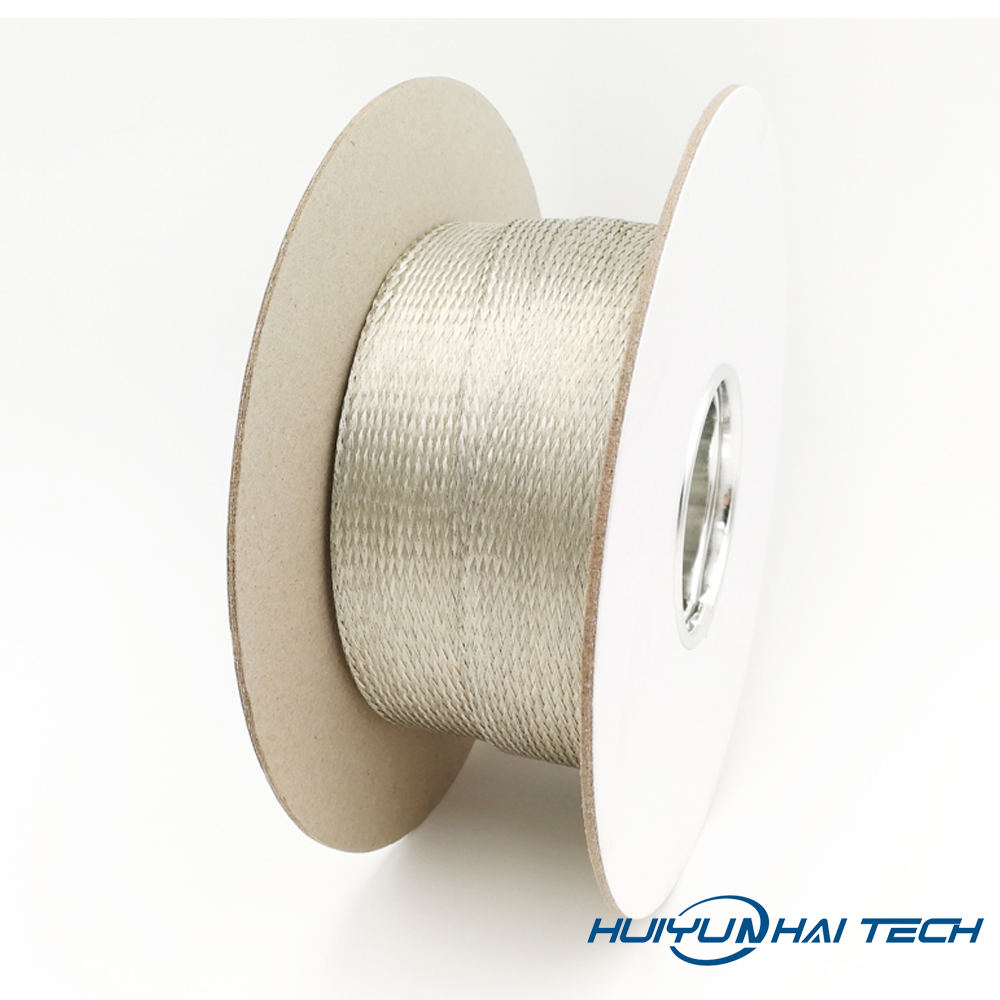

Color: silver

Nothing protects hoses from wear and blowout quite like real braided Tinned Copper Sleeve expandable sleeving. It looks great in any application and is strong and durable. But, custom overbraided hoses are expensive, selections are often limited and production and delivery times can be an issue.

Functions of Tinned Copper Braided Sleeving:

| NAME | Tinned Copper Metal Expandable Braided Sleeving For Cable Harness |

| Introduction | Stainless steel 304 metal braided sleeving is a high temperature, heat and flame resistant thermal insulating sleeve that will stand 900°C continuous exposure. The base High Temperature Braided Sleeve is fabricated from high quality type tiinned Copper Sleeve that will not burn. The sleeve is then coated with a vermiculite dispersant adds abrasion resistance and anti-fray properties.

|

| TYPE | EMI, RFI, ESD Protection |

| Material | Tinned Copper |

| Application | EMI, RFI, ESD protection Grounding straps Engine dress-up Military applications Extreme blowout protection Expands for easy installation

|

| Specification | By customers design |

1. Copper foil shielding sleeving is woven with copper foil filament,it is used for various electrical and industrial fields where EMI shielding, excellent protection and lightweight are required.

2. It is lighter and more flexible than tinned copper braided sleeving,it is a perfect conbination of economy and durability,it can be used as connectors with highly flexible and easily to install.

Details of tinner Copper Braided Sleeve

1) Multi-purpose metal braid provides shielding and grounding for equipment or wire harnesses , to protect your investment.

2) Expandable design allows for quick and easy installation of cable or wire bundles

3) Quality tinned copper braid can be easily soldered to connectors and used for custom-length earth straps.

4) Resists chemicals and the elements for use in rugged or exposed applications

5) Durable construction provides superior protection from accidental cuts or consistent abrasion

6) Easily cuts with shears, however heat shrink or electrical tape is recommended to terminate ends, to prevent them from fraying.

Description of metal tinned copper braided sleeving

Copper foil shielding sleeving is wowen with copper foil filament,it is used for various electrical and insustrial fields where EMI shielding,excellent protection and lightweight are required.It is lighter and more flexible than tinned cooper braided sleeving,it is a perfect combination of economy and durability,it can be used as connectors with highly flexible and easily to install.

braided copper wire used for the flexible conductor of electric installation,switch gear,electric frunace,storage battery,etc.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.