Expandable Metal braided Wire Sleeve For Engine Dress-up

Get Latest Price| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,EXW |

| Min. Order: | 500 Meter |

| Transportation: | Ocean,Air |

| Port: | Shenzhen Port,Yantian Port |

| Payment Type: | T/T,Western Union |

| Incoterm: | FOB,EXW |

| Min. Order: | 500 Meter |

| Transportation: | Ocean,Air |

| Port: | Shenzhen Port,Yantian Port |

Model No.: HYH

Brand: HYH

Sample: Free

Material: PET

Delivery: By Air

Certification: Other

Usage: Electric Wire

Type: Other

Lead Time: 4 Days

Color: Colorful Custom

| Selling Units | : | Meter |

| Package Type | : | roll and carton packing |

The file is encrypted. Please fill in the following information to continue accessing it

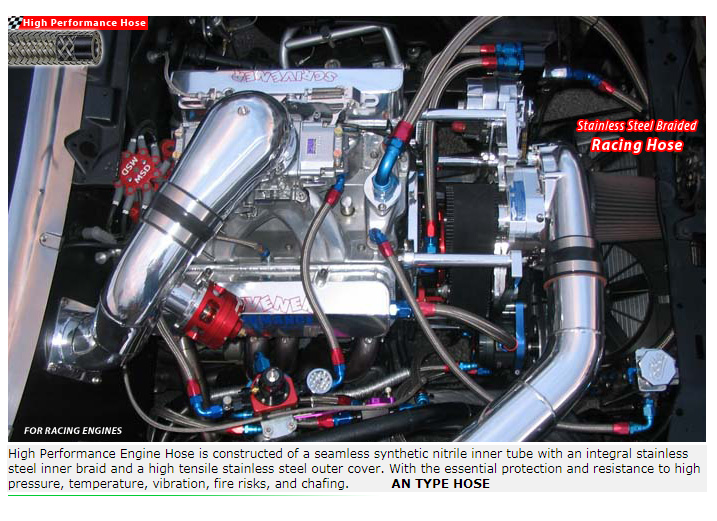

Introduction of Stainless Steel Braided Sleeve

Stainless steel 304 metal Braided sleeving is a high temperature, heat and flame resistant thermal insulating sleeve that will stand 900°C continuous exposure. The base high temperature braided sleeve is fabricated from high quality type stainless steel that will not burn. The sleeve is then coated with a vermiculite dispersant adds abrasion resistance and anti-fray properties.

Expandable Braided Sleeve compiled by the Environmental Protection PET filament diameter monofilament 0.20mm or 0.25mm's made with good flexibility, flame resistance, abrasion resistance and heat resistance, network management can be easily expanded to the original 150% , and it is easy to tighten the various irregularly shaped objects, which can be maintained within a wide temperature range while maintaining a soft, can inhibit chemical corrosion, UV and friction, characterized by its unique mesh also has good ventilation, wire heat diffusion function in a timely manner.

Functions of stainless steel sleeves

High physical strength with light weight and a long usage life.

1. high tensile resistant, strong vandalism resistant and strong corrosion resistant etc.

2. Reasonable construction, stable performance and superior electrical performance

3. can be installed directly, do not need preset tube or wire

4. Superior flexibility, smooth, easy for installation and position.

5. Good corrosion characteristics, resistance to high temperature, moisture, abrasion and penetration.

6. Good flexibility, absorb effectively vibration, noise, thermal expansion and contraction from pipeline system.

TYPE EMI, RFI, ESD Protection Material Stainless steel 304 Application

7. EMI, RFI, ESD protection

8. Grounding straps

9. Engine dress-up

10. Military applications

11. Extreme blowout protection

12. Expands for easy installation

13. Quick alternative for rigid piping in difficult locations, resolve minor deviation because of piping connecting and eliminate the pipeline residual stress, corrects problems of misalignment.

14. Applied to repeated motion areas, good anti-fatigue performance.

Application of metal braided sleeve

• EMI, RFI, ESD protection

• Grounding straps

• Engine dress-up

• Military applications

• Extreme blowout protection

• Expands for easy installation

• super high temperature resistant

Description for Braided Sleeving

Expandable braided sleeves is ideal for a limitless number of electronic, automotive, marine and industrial wire management and bundling applications. Examples include engine compartment dress up, home theater wire management, customizing computer case wiring, office wire management, automotive harnesses, scuba hose protection, and many more. Threads of different colors and textures could be braided into different patterns. Each of our products is tailored to the client's business and needs.

PET polyester expandable braided sleeving is flame-retardant and halogen-free. It offers durable abrasion resistance in a wide range of industrial applications. The open weave construction allows an easy installation on a bundle of hoses and cables, even if some with bulky or large connectors.

Totally expanded the sleeving can reach at least one point five times than the initial dimension.

Purpose: Tighten the power cord wire for protection.

With excellent flexibility, flame resistance, wear resistance and heat insulation.

Strong corrosion resistance and abrasion resistance.

Excellent softness, easy to bend.

Durable in use.

Can be used for wire and cable protection, pipe and hose, indoor wiring etc.

It offers durable abrasion resistance in a wide range of industrial applications.

The open weave construction allows an easy installation on a bundle of hoses and cables, even if some with bulky or large connectors.

Totally expanded the sleeving can reach at least one point five times than the initial dimension.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.